Duplex Cables: Your Essential Power Connection

Duplex cables play a crucial role in electrical distribution. Specifically, they deliver power safely from utility lines to buildings. Therefore, choosing the right duplex cable is very important. This guide explores what makes these cables essential.

What is a Duplex Cable?

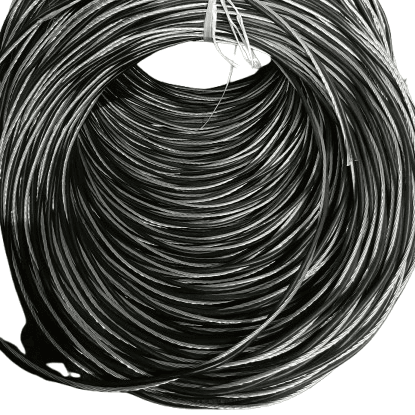

A duplex cable contains two insulated conductors. Typically, manufacturers bind these conductors together. One conductor usually carries the electrical phase. Meanwhile, the second conductor serves as the neutral line. Insulation covers each conductor individually. Furthermore, a web or outer layer often joins them side-by-side. This construction simplifies installation significantly. Essentially, it acts as the vital link for power entry. Many refer to this as the main line cable.

Key Features and Benefits

Duplex cables offer several advantages. Firstly, they provide reliable electrical transmission. Their design ensures consistent power flow. Secondly, installation is relatively straightforward. The paired structure makes handling easier for electricians. Moreover, manufacturers often use weather-resistant materials for insulation. Consequently, these cables withstand outdoor elements like the sun and rain effectively. Ultimately, this durability ensures a long service life.

Common Types: D11 and SQ Cables

Various types of duplex cables exist for different needs. For example, the D11 Cable is a specific type often used in service drop applications. The D11 Duplex cable configuration meets particular utility standards. Similarly, you might encounter SQ Cable designations. These often relate to quality standards or specific construction requirements. Regardless of the specific type like D11 or SQ Cable, their function as the main line cable remains primary. Thus, understanding these variations helps select the correct product.

Product Specifications

When selecting a duplex cable, consider its specifications carefully. Initially, identify the conductor material. Common options include aluminum (often Type 1350-H19) or sometimes copper. Aluminum offers a good balance of conductivity and weight. Next, check the conductor size. Sizes are specified in AWG (American Wire Gauge) or kcmil (MCM). Common sizes might range from #6 AWG up to 4/0 AWG or larger, depending on the load.

Furthermore, examine the insulation material. Cross-linked polyethylene (XLPE) is a popular choice. XLPE offers excellent resistance to heat, moisture, and abrasion. Polyvinyl chloride (PVC) is another possibility, though less common for service drops. Importantly, verify the voltage rating. A typical rating for service drop duplex cable is 600 volts.

Additionally, consider the temperature rating. This indicates the maximum safe operating temperature, often. Finally, ensure the cable meets relevant industry standards. Look for certifications like UL (Underwriters Laboratories) or compliance with ANSI/ICEA standards.

Primary Applications

The most common application for duplex cable is the overhead service drop. Specifically, utilities use it to connect the transformer on the pole to a building’s service entrance. This makes it the main line cable for homes and small commercial properties. Sometimes, contractors use duplex cables for temporary power during construction. However, its primary design serves permanent installations.

Choosing Quality

Selecting a high-quality duplex cable ensures safety and reliability. Therefore, always choose cables from reputable manufacturers. Check if the D11 Duplex cable meets your local utility requirements. Likewise, confirm any SQ Cable specifications needed for your project. Investing in a proper main line cable prevents future problems.

Reviews

There are no reviews yet.